Application: Used designing feed pellets for feeding cattle, geese, pig, duck, fish, chicken, sheep, rabbit, and other animals, livestock and poultry. If you need more than a single pellet mill, you might planning for setting up an automatic small scale animal feed pellet production line and start your own pellets making business.

.jpg)

Feed Pelletizing (Flat Die Pellet Mill): Small scale cattle feed pellet plant usually adopts flat die pellet machine to make the pellets due to its cost effective performance. The thickness and length of the cattle feed pellet can be customized by adjusting the flat die machine. Feed Pellet Cooling (Cooling Machine): The feed pellets coming from the pellet mill machine are at high temperature, the cooling machine can reduce the temperature and make the pellets more favorable for storage.

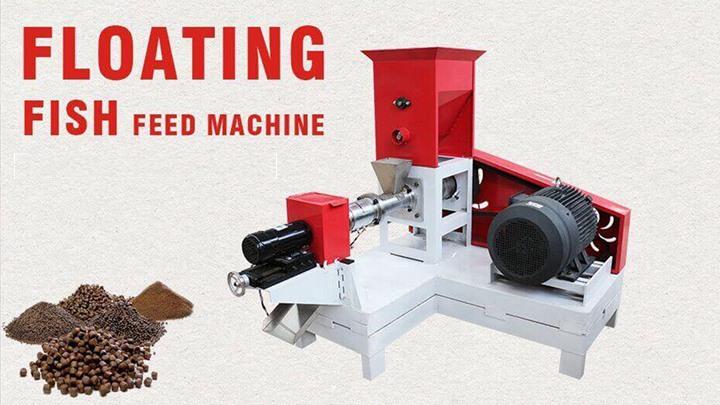

This is the most important equipment you’ll ever need in your business operation. Pellet mills take the raw materials and process them into pellet form. These are available in a range of capacities from 65-600 pounds per hour and prices start from $2,600. Take note that largerfish pieces need to be reduced to at least one-fourth inch before

Dairy Farming and Cattle Feed Machines | Lark EngineeringLark has designed pellet plants in compact configurations that have saved 50 % structure and required less space, without Tel:8619337889051 Email:sale@limamachinery.com

.jpg)

Different feed pellets require different compression ratio of ring die. So feed producers adopt corresponding ring die specification to ensure the feed pellet quality when making feed pellets for cattle in different stages. Cooling After leaving the pellet mill, the pellets have a temperature of 70-90℃ and the moisture of 15-17%.

This small pellet mill (granulation unit) enables you to make your pellets or animal feed granules from your own material. The granulation unit can be used for granulating sawdust, straw, biomass, paper, or for the granulation of feed and fodder mixtures, etc. Pellets are granules of a circular diameter of 6 to 14 mm and a length of 1 to 5 cm.

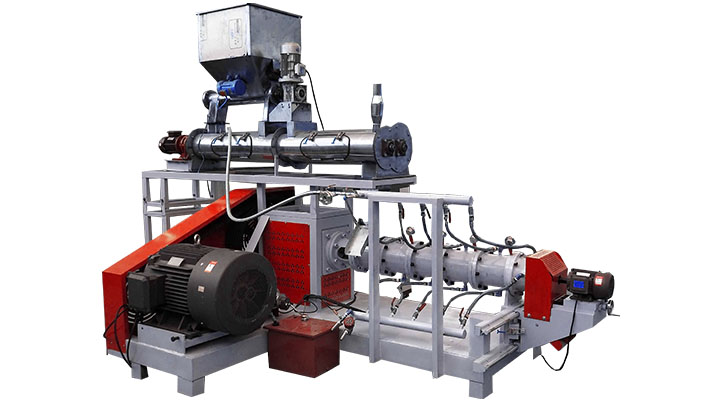

Equipment to Start Cattle Feed Production. A hammer mill is to crush the raw materials into small sizes to meet the requirement of a cattle feed making machine. Dryer machine is to dry the raw materials. Mixer is to mix multiple raw materials evenly. Animal feed pellet machine is to pelletizing the loose raw materials into high density cattle

.jpg)

Mar 07, 2019 · Ring Die Feed Pellet Mill. Ring Die Animal Feed Pellet Mill. As the name suggests, the ring die feed pellet mill has a wide cylindrical shape die and is mounted vertically. It mainly consists of feeding device, hardening and tempering device, conditioner device, press chamber transmission system, overload protection and electric control system.

.jpg)

For starting a cattle feed pellet making business you must purchase necessary animal feed machinery that are efficient and easy to operate. Your workers must be aware of how to handle this machine otherwise you might not get the result you were expecting initially. Create Pellets of Your Desired Size

.jpg)

Compound Feed Pellets. The compound feed (complete feed) contains starch, proteins, additives and the main feed that are meant for cattle. The main feed is mostly, pasture and corns. Legumes provide protein. Starch, also known as carbohydrates, are sourced from maize (corn) and wheat. Additives boosting the nutrition health of the cattle and

California Pellet Mill CPM CL Lab Mill. USED. Manufacturer: CPM. Used California Pellet Mill CPM lab mill, model CL, type 3, 3 hp, 460 volt main motor drive with VFD controller, .25 hp auger feeder with Eriez vibrating feeder with hopper, on stand with controls, serial# 277668 Cleveland, OH, USA. Click to Request Price.

.jpg)

The Pellet Mills we offer are designed using the latest technology for accurate and maximum output. The pellet diameter ranges from 2 mm to 25 mm capacity that can vary with the type of material and various other factors. Various pelleting application include Poultry / Cattle feed Pellets, Organic Fertilizers Pellets Plastic Waste Pellets

Main cattle feed production machinery. Feed hammer mill, utilized for crushing the raw materials into feed powder. Feed mixer also known as the feed mixing machine, adequately mixes the crushed materials to enhance the uniformity of the constituents. Additionally known as feed pellet mill is the key piece of equipment in this production process.

This feed pellet plant can produce 2~8mm of feed pellets with 600-1000kg/h pellet output capacity. The pellets are suitable for feeding pig, cattle, sheep, rabbit, chicken, duck, geese, fish and other animals. The grinding machine can crush the maize and soya bean meal into fine powder, then the fine powder can mix with the wheat bran, bone

The cattle feed pellets processing steps are as follows: Material selection: Choose the materials that can offer different nutrients that cattle need and suitable additives. Besides that, the share of each material should be strictly controlled as it can directly affect the durability of pellets. Crushing: Crush the materials into powdery